Hernta Manufacturing Process

The Process Behind

Our Strength

Hernta Manufacturing Process

Raw Material Coil

High-quality steel coils serve as the primary raw material, selected for their durability and suitability for various applications.

Coil Unreeler

The steel coil is placed on the unreeling machine to unroll the material smoothly for further processing.

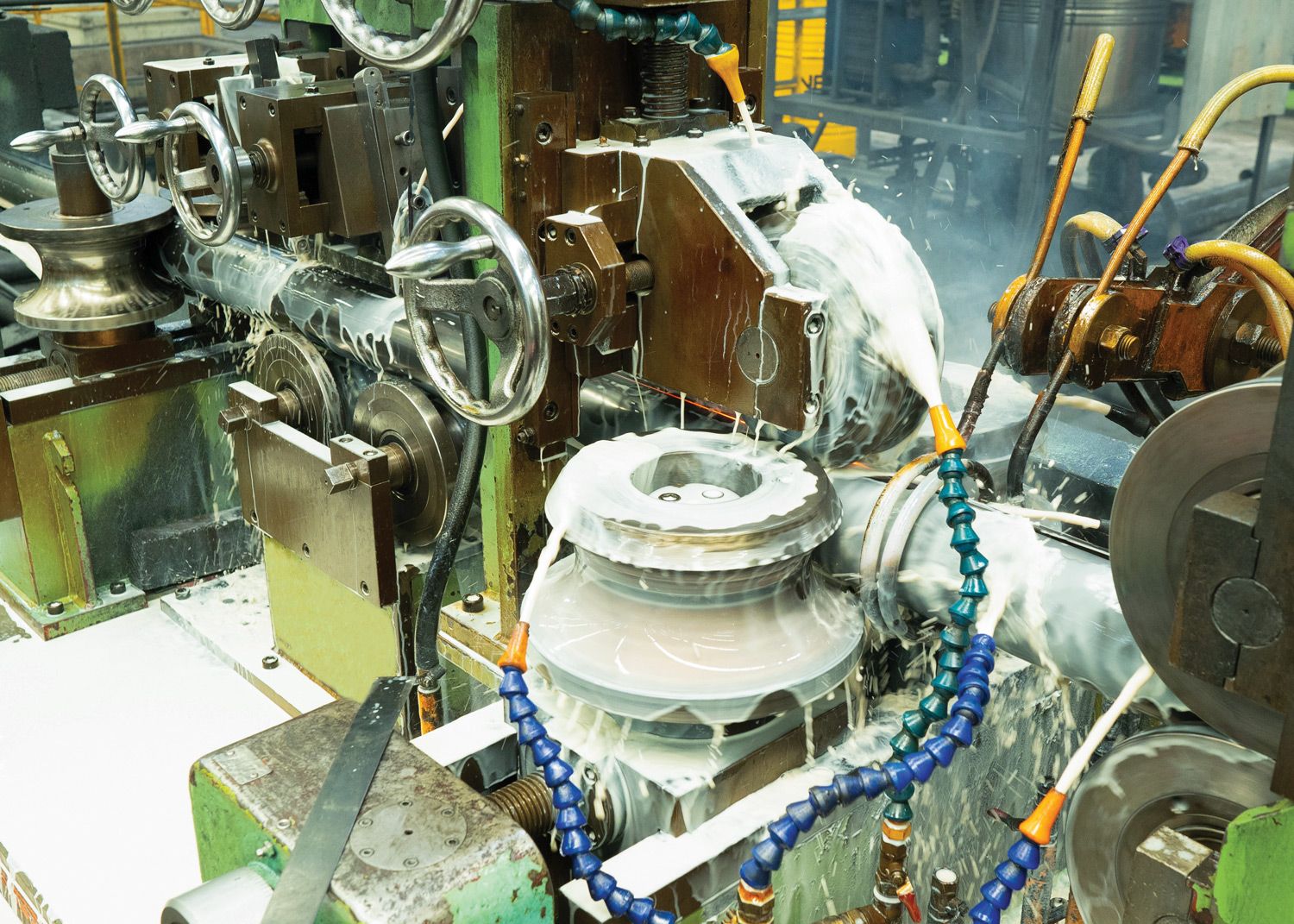

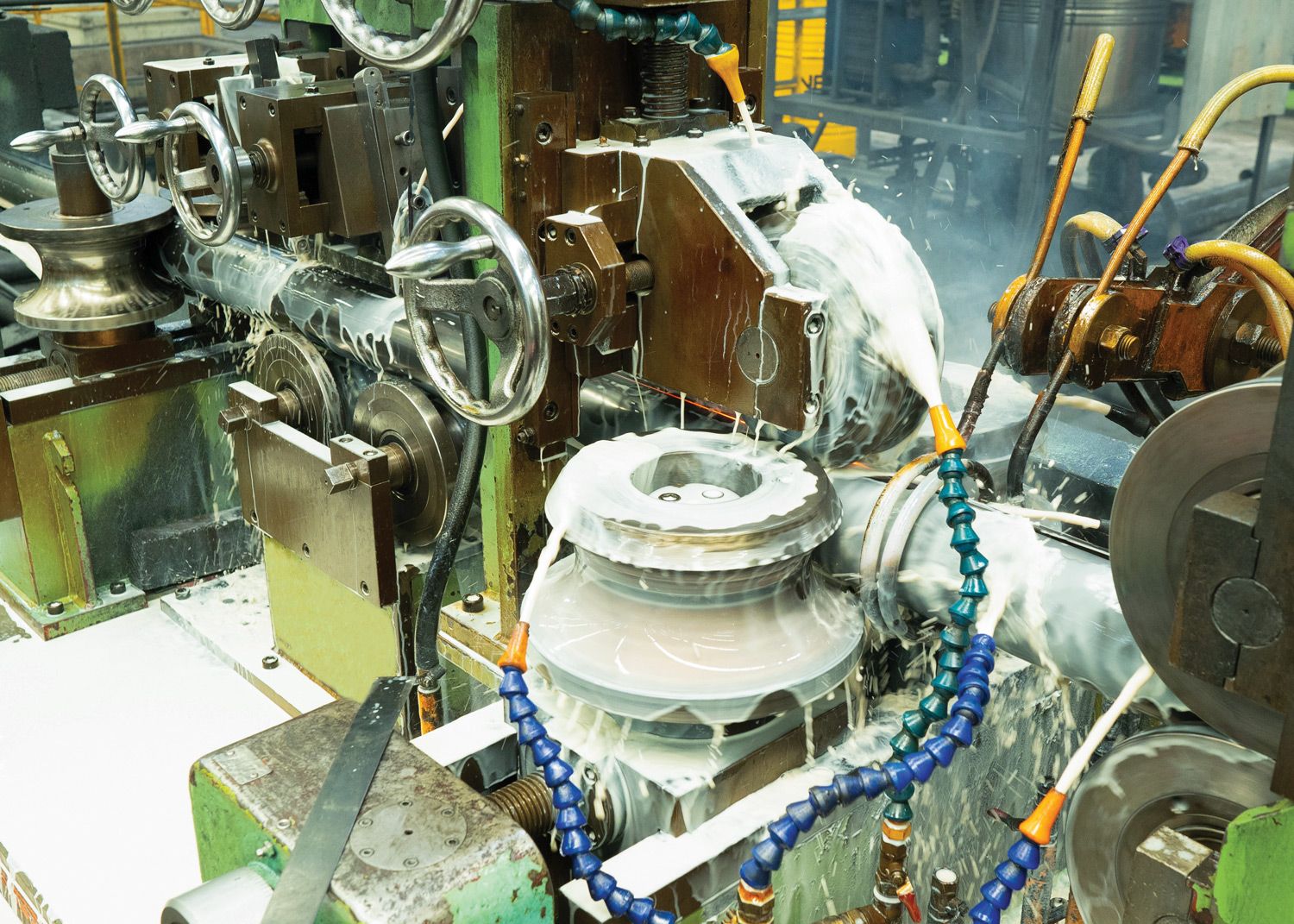

High-Frequency Induction Welder

Using high-frequency induction technology, the edges of the tubular steel are welded together, creating a solid and durable seam.

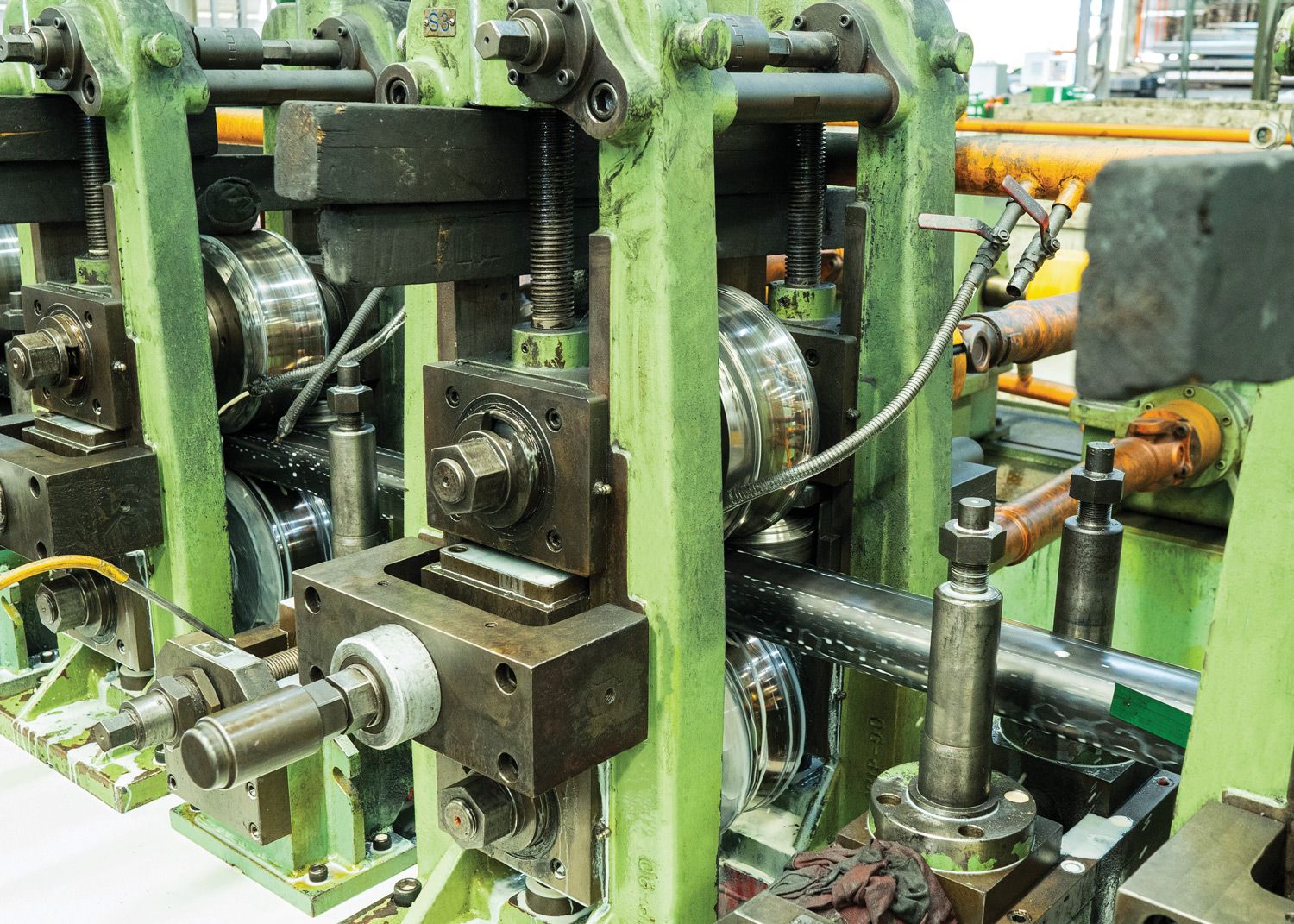

Roll and Gage Forming

The steel strip is progressively shaped into a tubular form using rolling and gaging equipment, ensuring dimensional accuracy and structural integrity.

Cooling Trough

The welded pipe passes through a cooling trough, which rapidly reduces its temperature to stabilize the structure.

Sizing

The pipe is resized to meet precise dimensional specifications, ensuring it meets customer and industry standards.

Strip Leveller

The unrolled steel strip passes through a levelling machine to ensure it is flat and ready for precise cutting and welding

Shear

The steel strip is cut to the required dimensions, eliminating rough edges to ensure uniformity in the subsequent processes.

Stamping

Identification markings or product information are stamped onto the steel strip, ensuring traceability and compliance with customer or regulatory requirements.

Coil Accumulator

The coil accumulator stores the continuous steel strip, allowing the production process to run without interruptions while preparing for the next step.

Cutting

The pipe is cut to the desired length using high-precision cutting equipment, based on customer requirements.

Run-Out Conveyor

The finished pipes are transported via a run-out conveyor, bundled, and securely packed for delivery, ensuring safe handling and transportation to the customer.